Servo Motor with Encoder and Driver /Drive/Controller/Stepper Motor/

Basic Info.

| Model NO. | PS1100 |

| Link of Transformation | AC-DC-AC Variable-Frequency Drive |

| Nature of DC Power | Voltage Variable-Frequency Drive |

| Function | Simple Type, Elevator Special, Textile Special, Constant Torque Universal Type |

| Transport Package | Cartons & Woody Box |

| Specification | 3 Years Warranty |

| Trademark | K-Drive |

| Origin | China |

| HS Code | 85044099 |

| Production Capacity | 200000PCS/Per Month |

Product Description

P Series AC Servo Catalogue,3 Years Warranty Frequency Converter

P Series AC Servo Catalogue

Brand: K-DriveCertificate: CE, RoHS Pulse Type AC Servo System

Product features

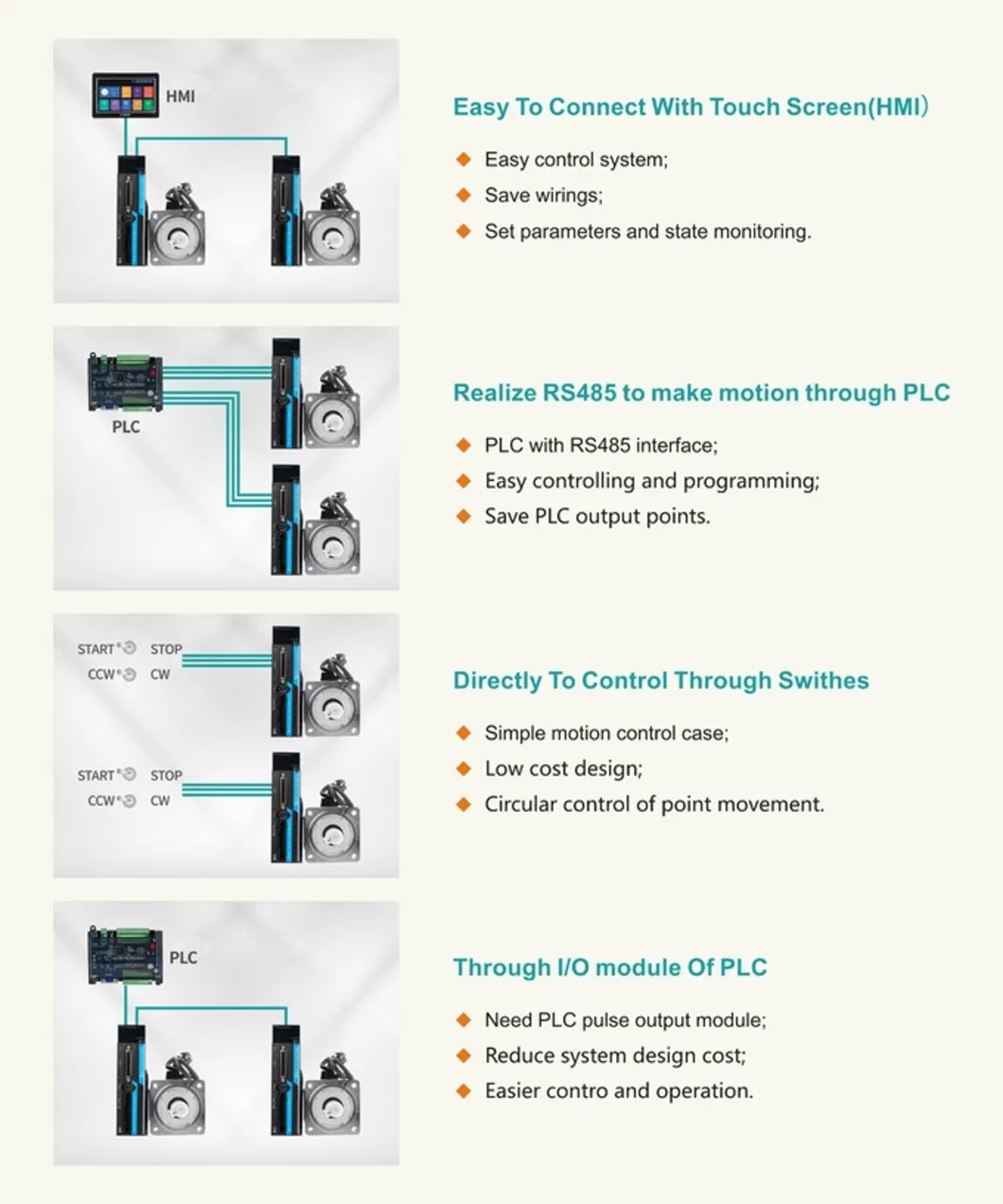

Strong internal motion control functions which can realize position, speed,torque,homing controlling modes. It also supports I/O control and standard Modbus RTU protocol. It can replace PLC partly, which helps to save cost.

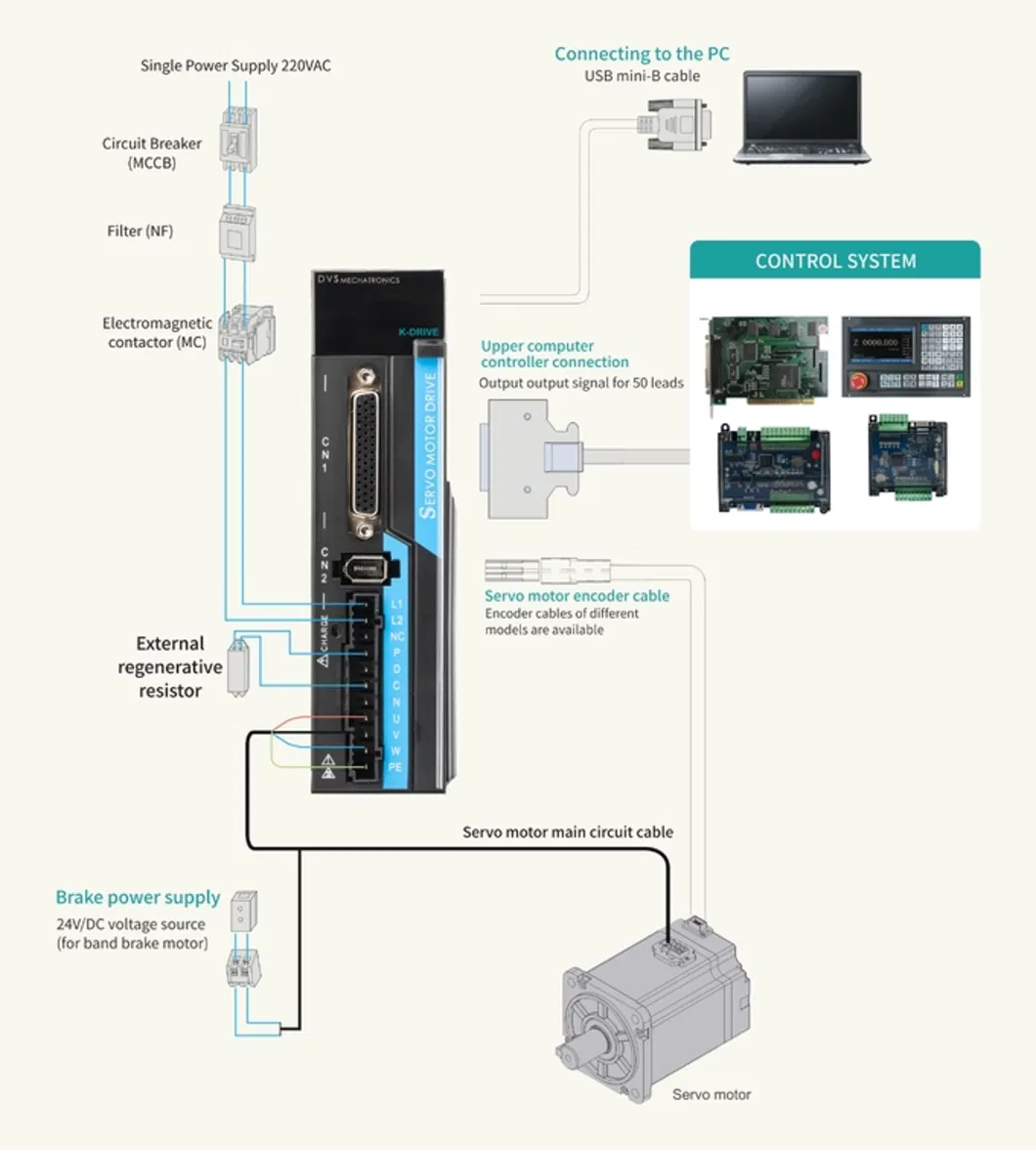

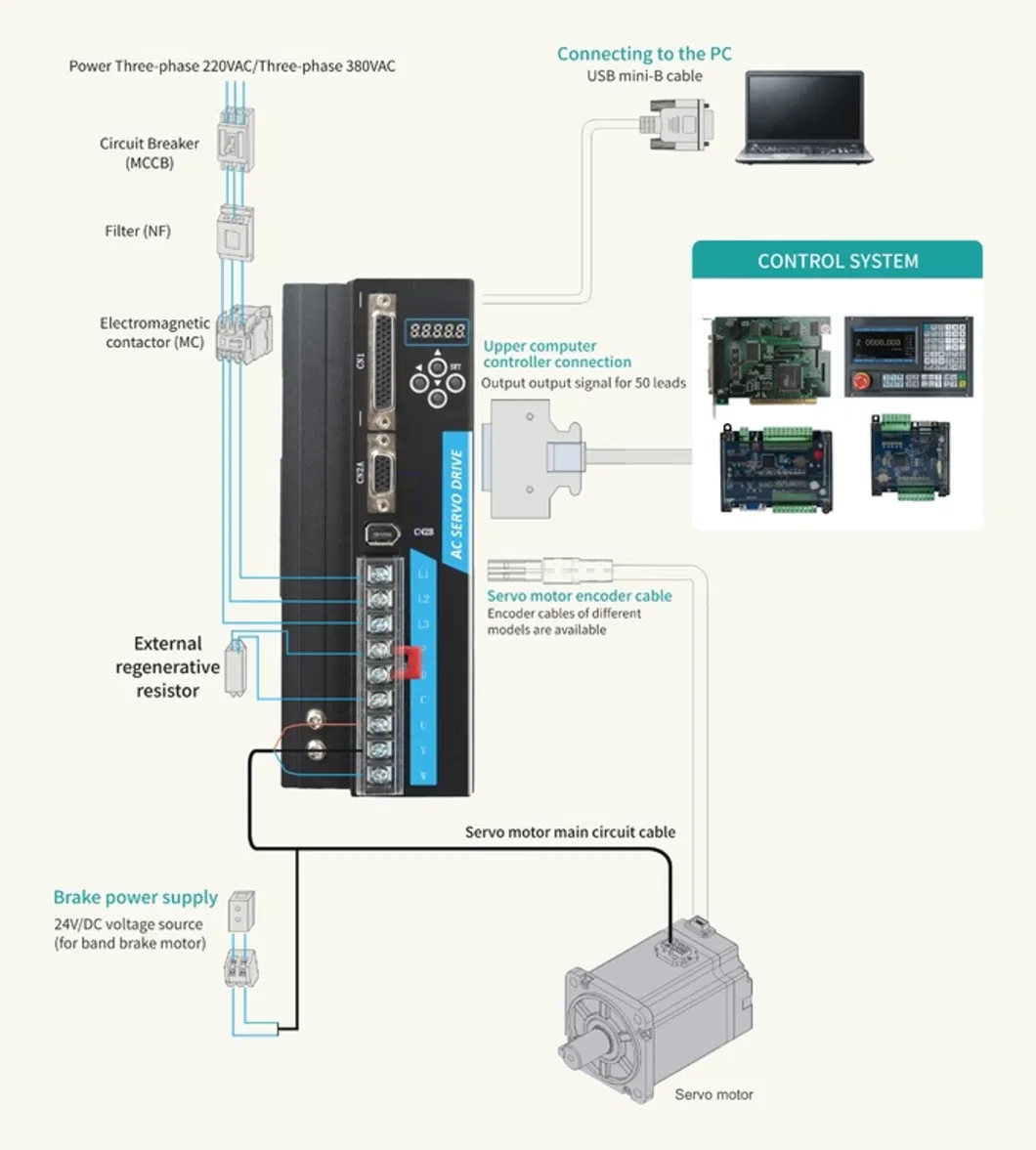

System Wiring Example

Drives Of P100S Series As Example:

Drives Of P300 Series As Example:

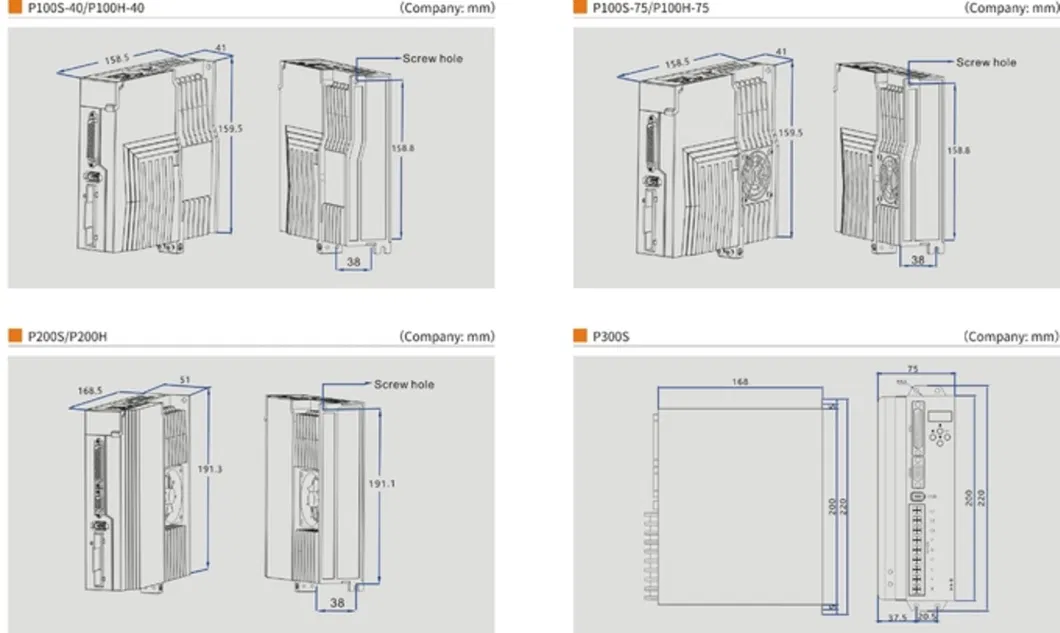

Dimension

Pecification

EtherCAT Bus Field AC Servos

Feature Introduction

System Wiring ExampleDimensionDrive Specification

Why choose K-Drive variable frequency drive?In the trend of advocating smart and simple industrial automation, environmentally friendly products, value-added solutions, K-Drive, as one of the world's leading drive manufacturers aggressively investing in R&D, production, and continuous quality improvement, is well positioned to provide its customers with technology-driven, performance-outstanding products such as VFDs, wind power converters, servo drives, HEV/EV drives, helping its customers save energy and increase industrial productivity with sustainability on the one hand, and enhancing their entire value-chain quality, delivery, and services on the other hand.

K-Drive VS Other brands

| Performance | Common brands | K-Drive |

|---|---|---|

| Applicable motors | Asynchronous motors | Asynchronous /synchronous motors |

| Starting torque | 2.0Hz, 150% (sensor-less vector control) 0Hz, 180% (closed-loop vector control) | 0.5Hz, 180% (sensor-less vector control) 0Hz, 200% (closed-loop vector control) |

| Speed adjustable range | 1:100 (SVC), 1:1000 (VC) | 1:200 (SVC), 1:1000 (VC) |

| Ambient temperature (no derating required) | -10-40ºC | -10-50ºC (for most of the models) |

| Rated input voltage | 208VAC-400VAC | 208VAC-480VAC |

| Communication | Modbus RTU//ASCII | Modbus RTU//ASCII Profibus-DP, CANopen, etc. |

| Position control (fixed length, or angular positioning) | × | √ |

| Field weakening control | × | √ |

| Autotune online | Online | Online & Offline |

| Short-time ramp-up | Trip | No trip |

| Customized features (software and/or hardware) | Unprocurable or no experience | Procurable with rich experience |

Production

In production, rigorous quality control is implemented on components, circuit boards, and the finished goods, assuring products without defects. What's ac servo ?An AC servo (alternating current servo) is a type of motion control system that uses AC (alternating current) signals to control the position, speed, and acceleration of a motor or actuator.

AC servo systems typically consist of a servo motor, a feedback device (such as an encoder), a servo drive or amplifier, and a controller or processor. The controller sends signals to the servo drive, which amplifies and converts the signals into high-frequency AC waveforms that are applied to the servo motor. The feedback device constantly monitors the position and velocity of the motor and sends this information back to the controller, which adjusts the signals to the servo drive to maintain the desired motion.

AC servo systems are often used in high-precision applications, such as robotics, machine tools, and automated manufacturing, where accurate and repeatable motion control is critical. They offer high speed and torque capabilities, fast response times, and precise positioning accuracy, making them ideal for applications that require high performance and reliability.