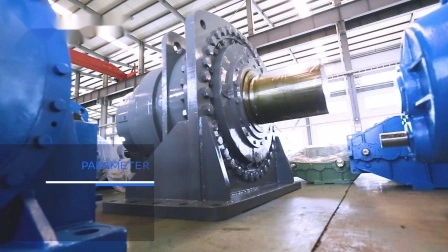

Disk Output Precision Planetary Reducer Servo Stepper Motor Special Flange Output Planetary Reducer

PLANETX planetary reduce Disc output reducer is widely used in industrial products due to its small size, light weight,

Basic Info.

| Model NO. | PLH090-L2 |

| Mechanical Process | CNC |

| Processing Trade | Processing with Material Supplied |

| Certification | ISO9001: 2000 |

| Customized | Non-Customized |

| Condition | New |

| Specification | PLH90-L2 |

| Trademark | PLANETX |

| Origin | China |

| HS Code | 8483402000 |

Product Description

Disc output reducer is widely used in industrial products due to its small size, light weight, large torque, wide speed ratio range, high rigidity, high precision, high transmission efficiency, maintenance free and other characteristics.

The planetary reducer structure is composed of a sun gear and a planet gear to form an external mesh, and a planet gear and an internal gear ring to form an internal mesh, so that the planet gear can realize revolution while realizing self rotation and maximum transmission of guarantee force; The minimum speed ratio of single-stage reduction is 3, and the maximum speed ratio is generally not more than 10. Common reduction ratios are 3, 4, 5, 6, 7, 8, and 10. The number of reducer stages is generally not more than 3, and the speed ratio is not more than 1000; The customized reducer with partial reduction ratio can achieve 4-5 levels of reduction, and the reduction ratio can reach 100000.

Most planetary reducers are used with servo motors to reduce speed, increase torque, increase inertia, and ensure return accuracy (the higher the return accuracy, the higher the price). The maximum rated input speed of planetary reducers can reach 12000 rpm (depending on the size of the reducer itself, the larger the reducer, the smaller the rated input speed), and the operating temperature is generally between - 40 ºC and 120 ºC.

Model | Unit | PLH064A PZH064A | PLH090A PZH090A | Ratios(i) | |

| Stages | |||||

Rated output torque | Nm | 16.5 | 63 | 3 | 1-stages |

| 26 | 90 | 4 | |||

| 28 | 100 | 5 | |||

| 20 | 68 | 7 | |||

| 12.5 | 43 | 10 | |||

| 19.5 | 75 | 9 | 2-stages | ||

| 31.5 | 110 | 12 | |||

| 31.5 | 110 | 16 | |||

| 31.5 | 110 | 20 | |||

| 33.5 | 120 | 25 | |||

| 31.5 | 110 | 28 | |||

| 33.5 | 120 | 35 | |||

| 31.5 | 110 | 40 | |||

| 33.5 | 120 | 50 | |||

| 24 | 81 | 70 | |||

| 37.5 | 130 | 80 | |||

| 37.5 | 130 | 100 | 3-stages | ||

| 40 | 145 | 125 | |||

| 37.5 | 130 | 140 | |||

| 40 | 145 | 175 | |||

| 37.5 | 130 | 200 | |||

| 40 | 145 | 250 | |||

| 37.5 | 130 | 280 | |||

| 40 | 145 | 350 | |||

| 37.5 | 130 | 400 | |||

| 40 | 145 | 500 | |||

| 28 | 95 | 700 | |||

| 18.8 | 62 | 1000 | |||

Max.output torque | Nm | 2/2*Nominal torqute | |||

| Backlash | arcmin | <4 | <4 | P1 | 1-stages |

| <8 | <8 | P2 | |||

| <8 | <8 | P1 | 2-stages | ||

| <12 | <12 | P2 | |||

| <10 | <10 | P1 | 3-stages | ||

| <14 | <14 | P2 | |||

| NO-load torque | NM | 0.18 | 0.6 | 1-stages | |

| 0.17 | 0.55 | 2-stegas | |||

| 0.16 | 0.5 | 3-stegas |

is based on the global industrial automation field. it is

saies of planetary reducers, hollow rotary platforrres,

a manufacturer specializing in R&D, production and

and special reducers. It belongs to "National High-tech

Enterprise". The headquarters and production center are located in Dongguan City,Guangdong Province, which is known as the "world factory", and there are service centers and transit warehouses in Beijing. Shanghai,Chengdu and other places.

The company's core team members have more than ten years of experience in the transmission industry and gear processing industry, and are good at solving a variety of internal and external gears and processing solutions. The company has summed up a complete set of "transmission quality management system" to ensure the relative accuracy of each component after combination,and provide high pass rate and high efficiency guarantee for the whole machine to leave the factory. We use advanced computer software for design and demonstration,combined with years of experience in mechanical transmission and motion

control, to provide global motion and control solutions. Our products have the characteristics of high precision, large bearing torque, long life, low noise, stable operation, strong versatility and maintenance-free Quality is the foundation of enterprise survival. We provide the market with stable and high-quality products and provide more optimized automation

solutions. Always take "user demand" as the business purpose of the enterprise, take "scientific and

technological innovation" as the foundation of the company's development, and implement the Iso

quality management system operation into all aspects of the company.

Our products are widely used in aerospace,CNC machine tools, cutting and welding equipment,textile printing and dyeing machinery packaging machinery, food machinerymedical machineryships,radardata communication systems,robots,robotic arms, composite materials equipmentprecision testing

Instruments, testing machines,plastic machinery, glass machinery,coal mining machinery,lifting machinery, metallurgical machinery,construction machinery and other fields.

The process of our pursuit of success is the process of continuous sublimation of our relationship with you. The success of the company is inseparable from the long-term support and help of many customers and friends. Facing the future, we will serve you more. Dongguan Planetx Transmission Equipment Co.,Ltd. will go hand in hand with you to create brilliant!

Q: How to get a quick quote

A: Please provide the following information when contacting us

- Motor brand

- Motor model

- Motor dimension drawing

- What is the gear ratio

A: We all install it now, but it takes 7 days if it is not non-standard. Non standard 15 days, depending on the specific situation

Q:Do you provide samples, free or extra

A: A: You can reserve one first, and purchase it on demand

previous:

NEMA23 2

Send to us