6.5inch 24V 150W 6.5n. M Electric DC Brushless Servo Wheel Hub Motor

Basic Info.

| Model NO. | ZLLG65ASM250-L |

| Function | Driving |

| Casing Protection | Closed Type |

| Number of Poles | 15 |

| Structure and Working Principle | Brushless |

| Type | DC Motor |

| Certification | ISO9001, CCC, CE |

| Brand | Zltech |

| Shaft | Single/Double |

| Protection Level | IP54 |

| Weight | 3.1kg |

| Encoder | 1024 |

| Rated Speed | 200rpm |

| Load | 120kg/2 Sets |

| Rated Current | 3~17A |

| Holding Torque | 6.5n.M |

| Transport Package | Single Item |

| Specification | 21cm*22.5cm*25cm |

| Trademark | ZLTECH |

| Origin | Shenzhen, China |

| HS Code | 8414909090 |

| Production Capacity | 50000/Year |

Packaging & Delivery

Package Size 41.00cm * 33.00cm * 23.50cm Package Gross Weight 5.000kgProduct Description

6.5inch 24V 150W 6.5N.m electric DC brushless servo hub motor wheel for AGV robotProduct Description| Voltage | 24v |

| Outside diameter | 6.5 inch |

| Encoder | 1024 line Incremental Photoelectric Encoder |

| Efficiency | ≥83% |

| Number of poles | 10 poles |

| Carrying weight | ≤120KG/2 sets |

| Shaft connection | thread |

| Brake method | electric brake |

| Excitation mode | permanent magnet type |

| Tyre form | with pattern |

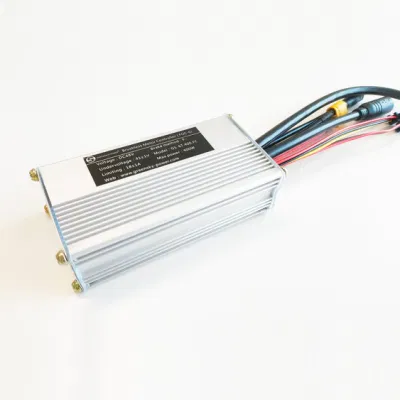

| Matching driver | ZLAC706/ZLAC706-CAN/ZLAC706-RC |

| Environment temperature | -10 ~ +40 degree centigrade |

Our hub drive motor advantage:

Self R & D, have own patent and great market competitiveness

- Built-in high precision encoder 12-21 bits optional, also can be customized, electric brake, high load carrying etc

- Simple structure, easy installation and high cost performance

- High precision, high power density, low noise

- The motor and the outer tyre are integrated, beautiful design

- 4-15 inch optional, power: 50-2KW optional, accept OEM/OEM for all models

More hub drive motor pictures:

Dimension of the servo hub motor single shaft:

Dimension of the servo hub motor double shaft:More Robot AGV dc hub servo motor:

Application: Service Robot, AGVBulk productionPatent for the hub motor:

Packaging & Shipping

Package: carton with foam, QTY per carton will depend on the hub motor size.

Shipping: goods will be deliveried by air(EMS, DHL, FedEx,TNT etc), by train or by boat according to your requirements.

Company Information

1. Brief introduction:

Shenzhen Zhongling Technology Co., Ltd. is a high-tech enterprise specialized in R&D, production and sales of industrial automation transmission products; The company gathered a large number of R&D elites being engaged in motion control field for more than 10 years and constantly provide cost-effective motion control products for our partners.

2. Product ranges and application:

Robot Hub Servo Motor, Digital Stepper Driver, Closed Loop Stepper Driver, Low-voltage DC Servo Driver and Stepper Motor, Multi-axis Motion Controller etc.. And widely used in hundreds of industries like Electronics, Machinery, Measurement, Laser, Medical, Textile, Packaging, LDE equipment, Channel Gates and Advertising etc.. Our products has win great popularity in global and been exported to global market like Southeast Asia, Europe and the United States etc.

3. Our service philosophy: Create value for customers.

4. Core value: Dedicated, innovative, virtuous, and pragmatic

5. Our vision: Being the most professional brand in the field of automation control, serving the global industry

About ZLTECH products in exhibition:

Contact:

FAQ

1. Factory or trader?

We are factory, and have professional R&D team as introduced in company information.

2. How about the delivery?

- Sample: 3-5 days.

- Bulk order: 15-30 days.

3. What is your after-sales services?

1. Free maintenance within 12 months guarantee, lifetime consultant.

2. Professional solutions in installation and maintence.

4. Why choose us?

1. Factory Price & 24/7 after-sale services.

2. From mold customization to material processing and welding, from fine components to finished assembly, 72 processes, 24 control points, strict aging, finished product inspection.